All around the world, Body Armour actively saves lives on a daily basis. Right from Special Forces undertaking a deadly mission, to the Police officials going about their daily beat patrols, all armed forces employ ballistic vests for their personal protection and operational enhancement. Hence, it becomes extremely crucial to fully understand the working of Armour Technology developed to provide protection to the heroes who stand bravely in the line of duty to safeguard their nation.

The main purpose of the Body Armour is to provide ballistic protection against edged weapons and to protect vital organs such as the heart, lungs, liver, kidneys, spleen, backbone, etc. This protection can also be extended to the thighs, the lower abdominal region as well arms.

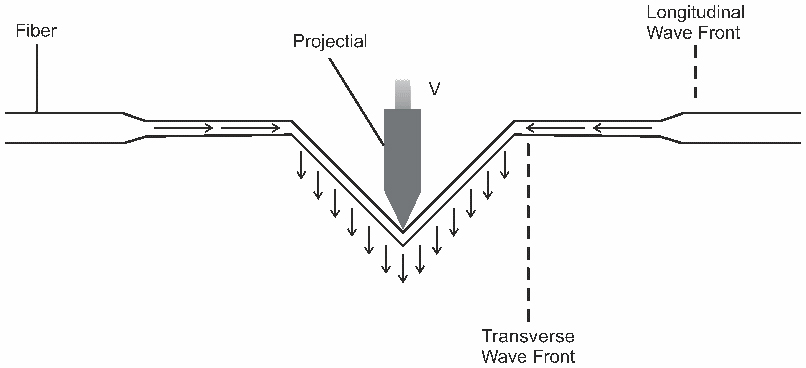

A ballistic material must pose very high strength that can absorb and dissipate the impact energy of a projectile in order to work efficiently. The energy dissipation characteristics of ballistic material largely depend on the sonic velocity of fibre and the construction of the material. The sonic velocity is related to the elastic modulus of a fibre. A higher elastic modulus results in the impact of energy to travel further and faster due to its higher sonic velocity and can be represented as follows:

C = √(E/ρ); where C= sonic velocity, E= Elastic modulus, ρ= fiber density

In other words, the principle on which body armour operates depends upon the rapid conversion and dispersion of the kinetic energy from a struck bullet.

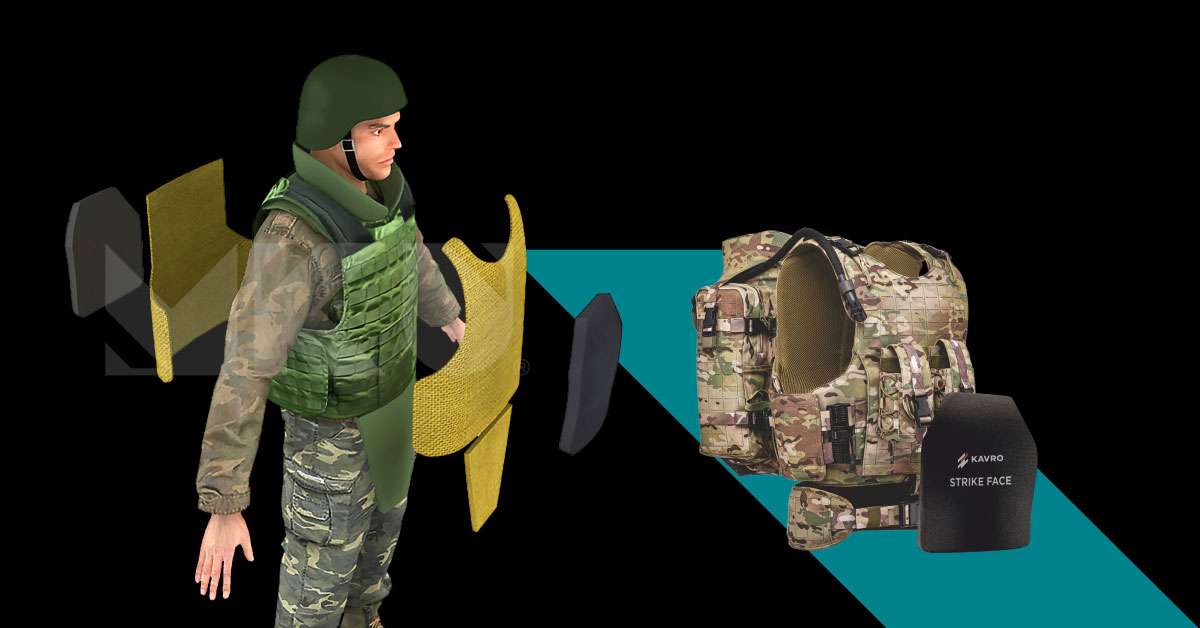

There are two main components of a bulletproof vest,

i) Soft Armour Plate,

ii) Hard Armour Panel

1) Soft Body Armour

Soft Armours are typically constructed with multiple layers of ballistic-resistant materials, stitched or glued in a particular fashion. It is designed to absorb energy whether from the impact of a bullet, or any other life-threatening source and disperse it over a wider area. It offers protection against threats mainly from handguns. It’s lighter in weight, flexible and durable making it suitable for extended daily wear. Soft body armour is usually made of a fabric-like material with extreme strength such as Para-Aramid, Ultra High Molecular Weight Polyethylene (UHMWPE), Liquid Crystalline Polymers, etc.

The following fibres are broadly used for manufacturing Soft Body armour:

Aromatic polyamide is also known as “Aramid” is a man-made high-performance fibre, with molecules that are characterized by relatively rigid polymer chains. These molecules are linked by strong hydrogen bonds that transfer mechanical stresses very efficiently, making it a chain of low molecular weight, high tenacity, tensile modulus, heat resistance, and chemical resistance, toughness, cut resistance, flame resistance, low electrical conductivity, thermal shrinkage, thermal conductivity and excellent dimensional stability. Yarns made from para-aramid fibres offer the best resilience to ballistic impact owing to their outstanding elasticity and elongation properties coupled with extremely high tenacities.

Figure: Pictorial representation of projectile impacting a single yarn fibre (image: elsveir)

Polyethylene is a thermoplastic, widely known as an Ultra High Molecular Weight Polyethylene (UHMWPE), and is manufactured by compressing the layers of a unidirectional UHMWPE fabric. These are mainly used in soft body armour for all protective levels.

Features of UHMWPE such as highest impact strength, lower density than the aramid fibre and excellent resistance against the chemicals make it the most suitable material for soft armours. It is used in different forms such as woven, laminated woven, non-woven, unidirectional (UD), multi-axial, etc.

2) Hard Armour Panel

As the name suggests, Hard Armours is rigid and are able to provide protection against rifle threats. Depending upon the nature of the threats it can generally be divided in various categories, primarily polyethylene body armour, ceramic and high strength fibrous material based armour.

There are various types of hard body armours discussed below:

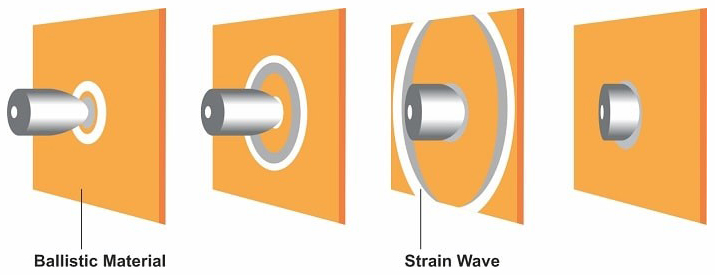

This works on the principle of Energy Dissipation. An incoming bullet is captured between the fibres’ layers and the energy of the speeding bullet is absorbed, eventually slowing it down and stopping the bullet.

Figure: Working Principle of Polyethylene Armour (image source: IEEE)

Due to various features in terms of physical and mechanical properties such as high abrasion resistance, high impact toughness, good corrosion, and chemical resistance, it’s widely used in making hard armour.

These types of fabrics are cut to shape, placed in the mould and compressed under high pressure and heat, resulting in a cohesive hard armour plate that helps in minimizing the friction caused by a bullets’ spin. This friction helps in melting the polyethylene and adheres to the round. When stopped, the polyethylene re-hardens as it cools down.

Ceramic Armour

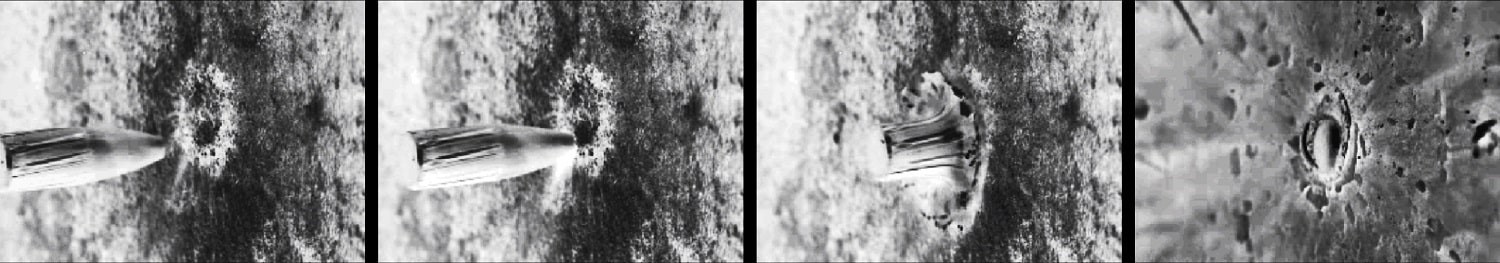

This works on the principle of Shattering/Breaking of Bullet that strikes the hard surface of Ceramic. It functions by shattering the speeding bullet and thus destroying the penetrative effect of the lead core or hard core bullet and this process leads to a small amount of energy dissipation.

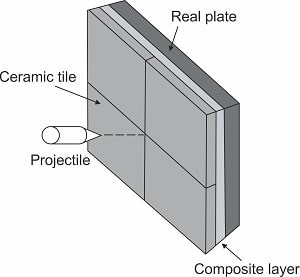

Figure: Working Principle of Ceramic Armour

Ceramic plates are used for the containment of blast fragments and the prevention of bullet penetration fired from rifles. They were developed strictly for projectile resistance with high hardness and compressive strength and an added advantage of being lightweight. The most common ceramic materials used for body armour applications are alumina, boron carbide, silicon carbide, and titanium diboride, etc.

Figure: A layered armour composite system with ceramic facing (image source: researchgate)

Ceramics are usually backed by composite backing layers (UHMWPE, carbon fibres, p-aramid fibres, etc, with or without the use of a metal plate in the rear. It consists of Controlled microstructures to ensure durability and performance in providing flexibility along with excellent resistance to stress rupture at temperatures up to 1650°C (3000°F).

Figure: Ceramic Plate image

Apart from the above-mentioned, steel and other metallic Armours are also in use but restricted in many cases due to their heavyweight.

Steel and other Metallic Armours

Many high-strength steel-aluminum alloys and titanium alloys are exceedingly being used as hard armours. The majority of the ballistic performance of these materials depends on parameters like strength, hardness, toughness, microstructure, strain hardening rate, etc. When used against high-powered ammunition, plates made from steel are effective to stop many types of bullet rounds and shrapnel but still do not make a valuable choice as they are heavy in weight and result in excessive chipping leading to secondary fragmentation injuries from the resulting shrapnel.

Conclusion

21st CE technologies have made protection against lethal, fast-moving projectiles much more achievable. At MKU, we further our Passion to Protect by utilizing only the best materials and manufacturing processes to make this life-saving gear. Click here to see the range of Kavro Body Armour manufactured by MKU

LOGIN

LOGIN