Since Soft Body armour serves a very astute operational requirement and is worn more from the perspective of protection and safety, it becomes extremely important to understand the working and materials usage of this type of armour.

Fig: Pictorial Representation of Soft Body Armour (Image: MKU)

Soft body armour is a form of wearable protective gear that is used to protect the body against low-velocity ballistic threats, including those from small hand-gun ammunition & sharp objects as well as other projectiles, against different internationally accepted test standards such as NIJ, HOSDB, VPAM, etc. Soft body armour is constructed with multiple layers of high-performance fabrics, making it lighter in weight and more flexible than a regular ballistic vest.

To manufacture soft body armour, multiple layers of woven or unidirectional fabrics, made from high-performance fibres are stitched and compressed together to prepare the soft body armour panels. Material properties are of paramount importance while manufacturing this life-saving vest. Fibres used for armour applications require these basic properties like having low density, high tensile modulus, high tenacity, and low elongation at break.

Designing Soft Body Armour:

The principal factors that dictate the design of any type of body armour are the type(s) of threats for which the protection is primarily required. Weight, mobility, and comfort are therefore very important factors to consider in ensuring that the armours conform to the user’s body. Thus, the proper distribution of armour weight and ergonomic design helps in minimizing user fatigue and makes it capable of being donned for longer durations.

Nowadays, soft body armours used for ballistic protection are worn to protect the torso and extremity regions. They are developed in accordance with rigorous standards and specifications to ensure proper performance and reliability levels against ballistic and fragment threats. Soft body armour is undeniably a lifesaving technology that employs blended layers of tough synthetic fibres to catch bullets in their tracks.

Materials used for making Soft body armour:

High-performance fibres are actively used in soft based armours by police officers and security personnel to achieve the desired protection. High-performance fibres used for such purposes include p-Aramid, Ultra-high molecular weight polyethylene or UHMWPE etc. Each of these materials have high tenacity (20-45 gpd), high modulus (700-2000 gpd) with a low density (0.97-1.45g/cm3).

1. Ultra High Molecular Weight Polyethylene (UHMWPE):

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very rugged material, with the highest impact strength of any thermoplastic in existence.

Fig: Chemical formula of UHMWPE (Image: fluorocarbon)

It is highly resistant to corrosive chemicals, has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating and highly resistant to abrasion, in some forms being 15 times more resistant to abrasion than carbon steel.

UHMWPE fibres are commonly used in soft body armor and have contributed to vast improvements when it is compared with p-aramid fibres making them 40% stronger. For body armor, the fibres are aligned and bonded into sheets, which are then layered at various angles to give the resulting composite material strength in all directions.

Primary reasons to use UHMWPE fibre:

1. It offers excellent resistance to stress and cuts

2. Its high strength-to-weight ratio makes it hard to penetrate on impact.

3. It has strong chemical resistance and is highly resilient to most alkalis and acids etc and saves the vest from extreme deterioration.

4. They have low density making the vest lightweight and can also be used for floatable ballistic vests.

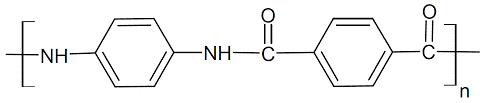

2. Para-aramid:

These materials are derived from a group called ‘aromatic polyamides’. These are synthetic fibres that have high resistance to abrasion, low density, high tensile strength and modulus. The polymers in aramid fibres contain phenol rings joined together through ‘amide groups. It is this unique structure that gives them unmatched strength.

Fig: Chemical Structure of Para-aramid fibre (Image: Polymerdatabase)

Primary reasons to use p-Aramid fibre:

1. The high strength-to-weight ratio makes them extremely capable of utilizing and increasing the performance of reinforced material in their composites. The aramids are tough, structurally rigid, and offer high cut resistance.

2. Their molecules are linked with an ultra-strong hydrogen bond that helps in transferring mechanical stress very efficiently.

3. Its high strength-to-weight ratio and exceptional heat resistance make aramids suitable for wide applications in ballistic vest manufacturing.

At MKU, we conduct constant and rigorous quality checks on the materials we use to make our vests. Continuous evaluation of ballistic solutions and their resulting performance through our exhaustive testing process, through accredited international laboratories, is maintained as mandatory. We strive to offer our customers the very best protective armour ensuring the usage of proven materials only for extraordinarily improved ballistic protection levels, while being significantly lightweight and hence enhancing the effectiveness and mobility of military troops, police officers and security personnel.

LOGIN

LOGIN